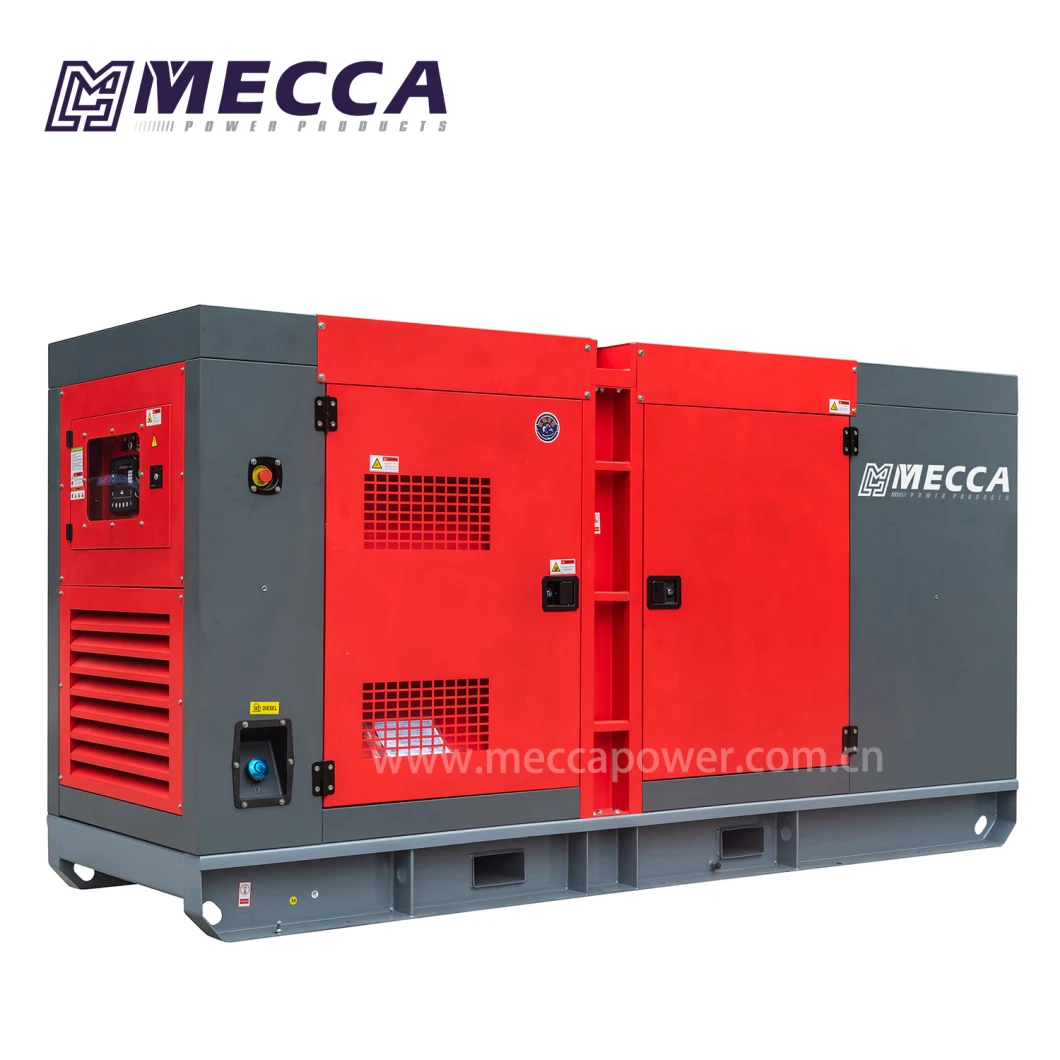

110kVA 3 Fase 4htaa4.3-G21 Sdec Motor Chinês Diesel Gerador de Energia

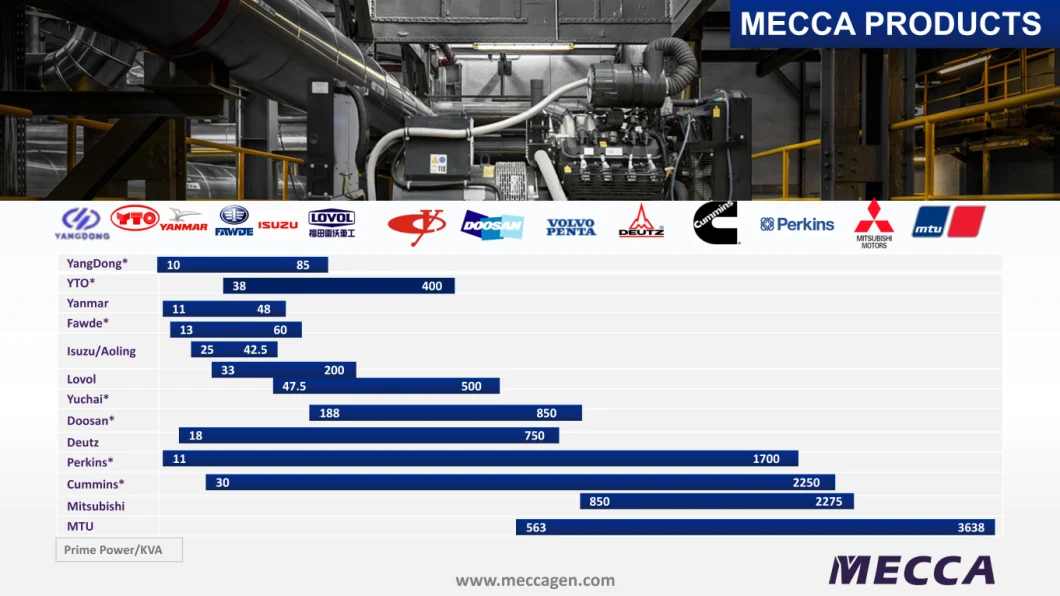

A Mecca Power, como parte de uma iniciativa Global Power Supplier, fornece uma solução profissional para o projeto, apli

Descrição

Informação básica

| Modelo Nº. | MC |

| Tipo de saída | CA trifásica |

| Velocidade | Baixa velocidade |

| Condições de Uso | Uso da terra |

| Uso | Unidades Comuns, Unidade de Espera, Tripulação de Emergência |

| Tipo de Unidade de Uso do Solo | Tipo de automação |

| Modo de Excitação | excitador estático |

| Marca do motor | Dec do Motor Chinês |

| Marca do alternador | Meca, Leroy Somer, Stamford |

| Painel de controle | Deepsea/Comap/Datakom/Delixi/Smartgen e outros |

| Gerador de motor a diesel | Conjunto gerador de partida elétrica elétrica |

| Tipo de Capota | Silencioso à prova de som/à prova de intempéries/à prova de ferrugem |

| Frequência (Hz) | 50Hz/60Hz |

| Saída de Tensão | 230/400V |

| Aplicativo | Mineração/Hospital/Construção/Aluguel |

| Acessório[a] | Documentos de peças sobressalentes |

| Acessório[B] | Conjunto de ferramentas |

| Tipo Governante | Mecânico/Elec/ECU/Ecm/Adec/Hpcr |

| Certificado disponível | CE, ISO, Autorização OEM etc. |

| Grupo Gerador a Diesel | Gerador movido a diesel |

| Grupo Gerador |

Introduction of Maintenance grade(Interval) for the generator set A Level Maintenance Interval (Daily Maintenance)1. Check Daily Report of Genset .2. Check fuel level and coolant level. 3. Check alternator for cracks or other damage, and the condition of the belts must be checked, flab or other damage.4. Check the Air filter. The air filter should be replaced when necessary .5. Release fuel tank and fuel filter's water and sediment.6. Check the water cooling filter.7. Check starting battery and electrolyte, add electrolyte when necessary. 8. Check the starter, check noisy defect.9. Use air syringe cleaner to clean the water tank, coolant system and cooled fin net.B Level Maintenance Interval (Less than 400 hours)1. Repeatedly check A Level Daily Maintenance steps.2. After operating 100 to 250 hours, replace the fuel filter. All the fuel filters should not be cleaned, it should be replaced. 100 to 250 hours is just flexible time, actually it must be according to the practice and real fact. 3. After operating 200 to 250 hours, replace the oil & oil filter. All the lube oil must fit up to the CF Grade of American Petroleum Institute.4. After operating 300 to 400 hours, replace the air filter. The air filter can be cleaned with air syringe, or it can be replaced. The replacement must be according to the environment and real fact.5. Replace the cooling system and add coolant concentration.6. Clean the crankshaft and inlet, outlet air- filter net. C Level Maintenance Interval (2000-3000 hours), Please do as follows:1. Repeatedly check A and B Level Daily Maintenance steps.2. Remove the tap of valve, clean and wash oil dirt and sludge.3. Fasten snails from each part (including running parts and fixed parts)4. Clean and wash the crankcase, oil sludge, steel scraps and sediment with engine.5. Check wearing of the engine turbo, clean and wash accumulation of carbon, adjust it when necessary.6. Check and adjust valve clearance.7. Check PT pump, quality of injection, adjust injection process, adjust it when necessary.8. Check and adjust the tension of fan belt and water pump belt, adjust and replace it when necessary; clean and wash water tank radiator fins, then check the using capability of thermostat.Current Repair (D Level Maintenance)(3000-4000 hours)1. Check valve, valve seat and other wearing, repair or change it when necessary.2. Check P pump, quality of injection, repair and adjust it when necessary.3. Check and adjust connecting rod and fastening twisting torque.4. Check and adjust valve clearance.5. Check the trip of injector.6. Check and adjust tension of fan and generating belt.7. Clean and wash accumulation of carbon in inlet pipes.8. Clean and wash the core of air cooler.9. Clean and wash the whole oil lubrication system.10. Clean and wash room of rocker arm, oil sludge in the sump and Metal scrap-iron.Medium Repair (6000-8000 hours)1. Including the items of minor repair.2. Disassemble generator(except crankshaft)3. Check the easy worn spare parts in pitman shaft system, gas distribution system, lubrication system, cooling system of cylinder, Piston, Intake and exhaust valve, replace them when necessary.4. Check fuel supplying system, adjust oil pump and injector.5. Repair and test the alternator, clean oil-sediment and lubricate the bearing of alternator.Overhaul (9000-15000hours)1. Including the items of intermediate repair.2. Disassemble all the parts in the generator.3. Replace cylinder, piston, piston loop, big and small bearing bushes, trusting pad of crankshaft, intake and exhaust valve, a whole set of tools for generator repair 4. Adjust oil pump, injector and replace pump core, injector5. Replace a whole set of repair tools for turbo charger and a repair set for water pump.6. Adjust the parts of connecting rod, crankshaft and generator body,repair or replace them when necessary

Anterior: Tocha de corte de plasma AG60 de alta frequência 60AMP com novo design

Próximo: Get Star Weld 150A MIG/Mag 15ak MB15ak 3m pistola portátil CO2 MIG tocha resfriada a gás

Nosso contato

Envie agora